Featured

How To Calculate Control Limits For X Bar Chart

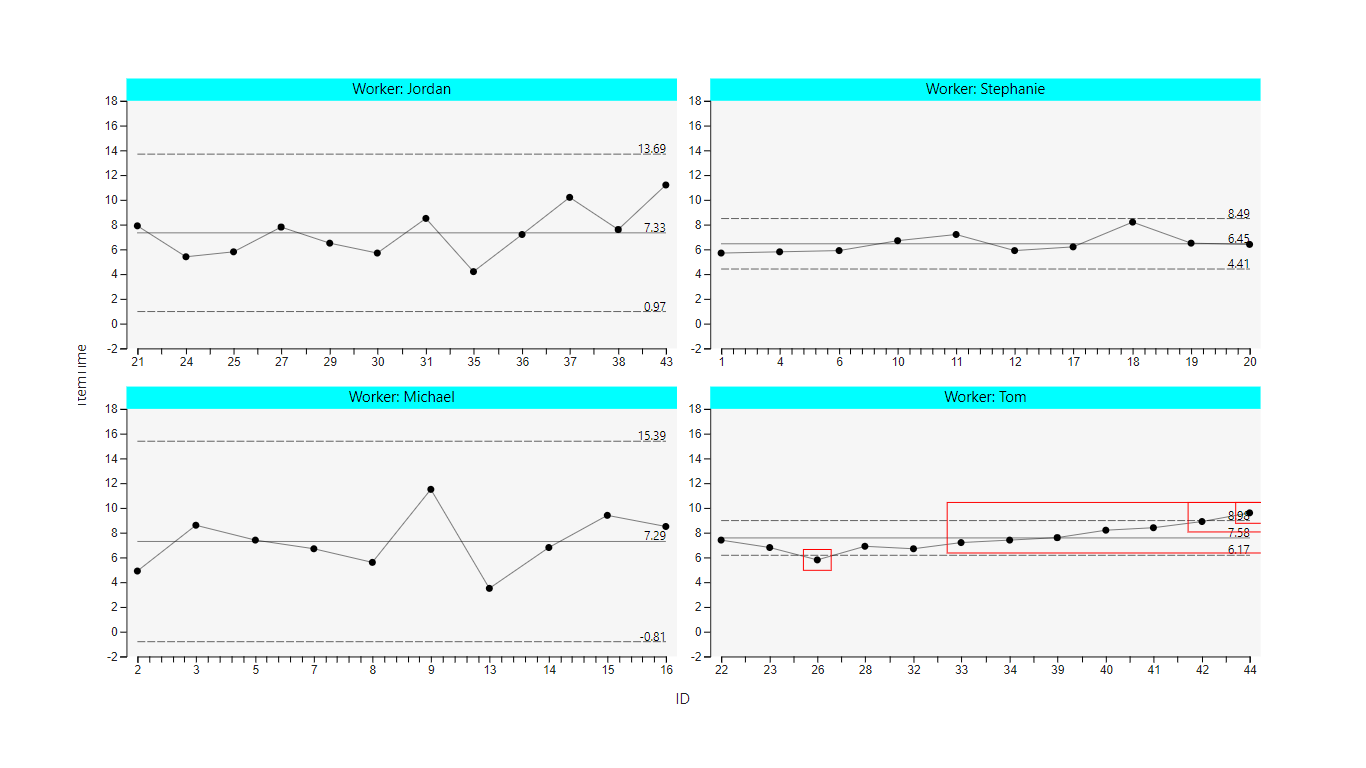

How To Calculate Control Limits For X Bar Chart. By default, minitab calculates the control limits using the actual subgroup sizes. Minitab labels the lower bound as lb and the upper bound as ub.

Place bounds on control limits. By default, minitab calculates the control limits using the actual subgroup sizes. Upload your data to trendable for data analysis.

Force Control Limits To Be Straight.

Select k successive subgroups where k is at least 20, in which there are n. Create/select specification limits specific to the data.*. The mean or average change in process over time from subgroup values.

Calculating 3 Sigma Control Limits.

When the subgroup sizes differ, the control limits are uneven, but you. The mean or average change in process over time from subgroup values. Calculate the average of the s values.

If The S Chart Validates That The Process Variation Is In Statistical Control, The Xbar Chart Is Constructed.

Calculate ¯¯x x ¯ ¯. To compute the control limits for the \bar{x} chart we use \bar{\bar{x}} as an estimate of the process center (or mean) μ. You can specify a lower bound and an upper bound for the control limits.

By Default, Minitab Calculates The Control Limits Using The Actual Subgroup Sizes.

Minitab labels the lower bound as lb and the upper bound as ub. Using the information below, calculate the proper control charts limits. This is the centerline of the s control chart.

The Sigma Of The Whole Data Set Is Calculated As Rbar/D2 (D2=1.128) Now, Take That Method 2 Standard Deviation And Divide It.

The r chart is the control chart for the subgroup ranges. This chart must exhibit control in order to. The constant 2.66 is sometimes used to calculate xmr chart limits.

Popular Posts

Calculate Index Of Hydrogen Deficiency

- Get link

- X

- Other Apps

Tabla Para Calcular Números De Loterías

- Get link

- X

- Other Apps

Comments

Post a Comment